METALWORK | PLASTICS | CARPENTRY

METALWORK

Machinery specialized in metal processing. The high level of technology and diversity of the machinery operated by KENFOSTER Building Retail guarantees safety, quality, speed, and the lowest possible cost per unit.

A selection of machinery we operate:

High Powered Beam Lasers from the latest technology for: cutting, drilling, surface treatment, welding, engraving.

Machining units - Turning / Milling: Digitally controlled CNC lathes and milling machines.

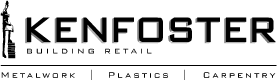

Calendering and CNC Calendering.

Sheet metal and steel punching. The running of the plant is carried out directly by the technical department equipped with a CAD/CAM system directly integrated with the production centre.

Shearing - CNC Hydraulic Shear. Cutting capacity: maximum length 5000 mm.

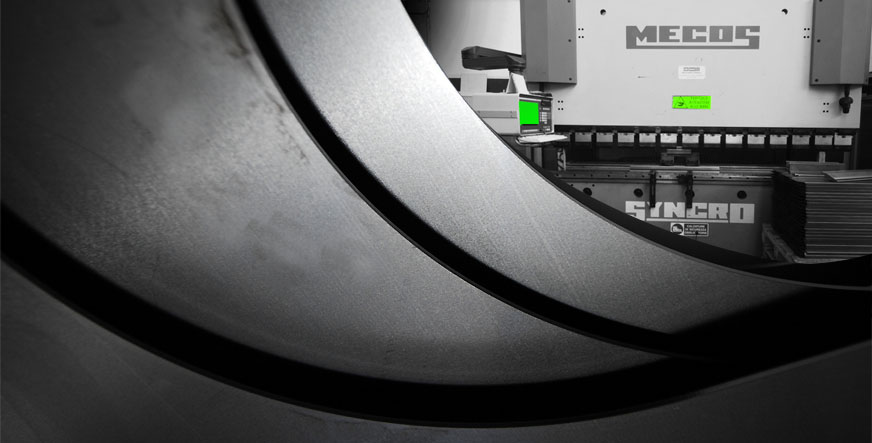

Bending - Hydraulic Press. Cold bending by hydraulic press allows for the development of detailed sheets of metal which are either bent or annular.

Calendering. Calendering makes it possible to modify the shape and curvature of flat sheets with varying radial dimensions.

TIG Welding - Wire (MIG-MAG) - spot - capacitor discharge plasma - electrode - with addition of tin.

Satinizing: We have orbital and linear two-axis sanders with a work area of 4000x2000 that facilitate the creation of special designs on sheets of iron, aluminum and stainless steel.

PLASTICS

Machinery specialized in the processing of plastics. The high level of technology and diversity of the machinery operated by KENFOSTER Building Retail guarantees safety, quality, speed, and the lowest possible cost per unit.

A selection of the machinery we operate:

Surface pre-treatment equipment: EDM.

Milling machines: with 3-4-5 axes with milling tool changer.

Decoration and finishing: EDM machines.

Machinery for rapid prototyping: stereolithography.

Machines for rotational moulding.

Machines for slitting and peeling.

Multi-component injection machines.

Injection machines for general use.

Injection moulding machines for plastics.

Machinery and equipment for extrusion embossing, coating, and coupling.

Machinery and equipment for recycling.

Welding, manipulators, injection molding.

Moulds and hot runners.

Thermoforming.

CARPENTRY

Machinery specialized in wood processing. The high level of technology and diversity of the machinery operated by KENFOSTER Building Retail guarantees safety, quality, speed, and the lowest possible cost per unit.

A selection of the machinery we operate:

CNC line for composite and solid wood panel processing.

CNC drilling machines.

Wood profile sander - 3 belt sanding units.

Hydraulic automated veneer cutting machine.

Paint smoother.

Vacuum wood dryer – 10 cubic metres.

Veneer splicing machine (wire).

Hot press machine.

Double sided calibrating sander.

Sanding bench - 3 aspirant walls.

Modular sawdust suction system - 24 inlets.

Double-end Cutting Saw.

Toupie with extended work area.

Press for wood laminated beams.